Product & Service

PC Peripherals

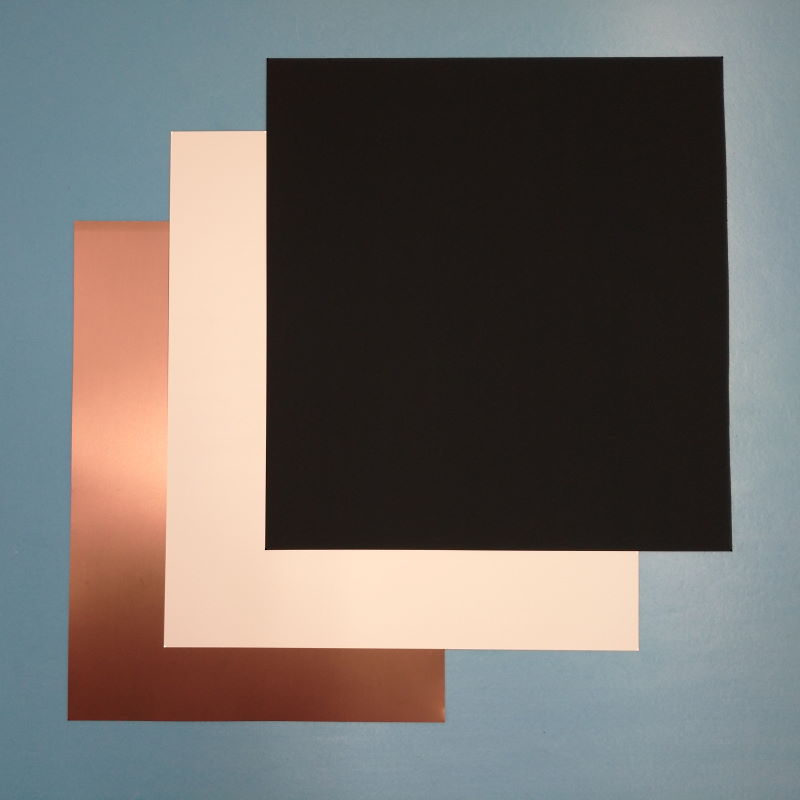

LaZ - low CTE core & PP material

Sumitomo Bakelite low CTE material, including core and prepreg, are used to produce low warpage IC substrate. The developing trends and characteristics of electrical products are thin and light. Sumitomo low CTE materials are capable to provide the best solution for IC substrate, in terms of warpage and reliability testing performance. Now, worldwide IC design houses are starting to use Sumitomo low CTE materials for IC substrate mass production. Application: Plastic Substrate、Ultra-thin passsitive component substrate、Flexural Circuit Board.

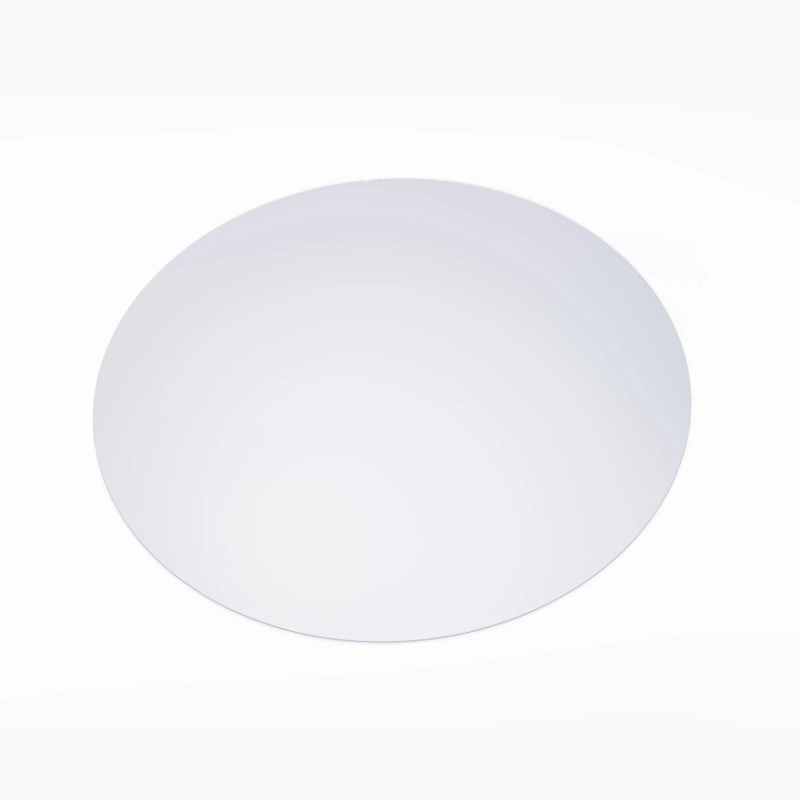

Dummy & Monitor Wafer

Product:12"Silicon Wafer Reclaim Service/12" Monitor wafer/12" Dummy wafer /12" Test wafer. We supply high quality reclaim wafers processed by the most advanced equipments and high level polishing and cleaning technology. We also supply 12" monitor / 12" dummy & 12" Test wafers that meet customer's need.

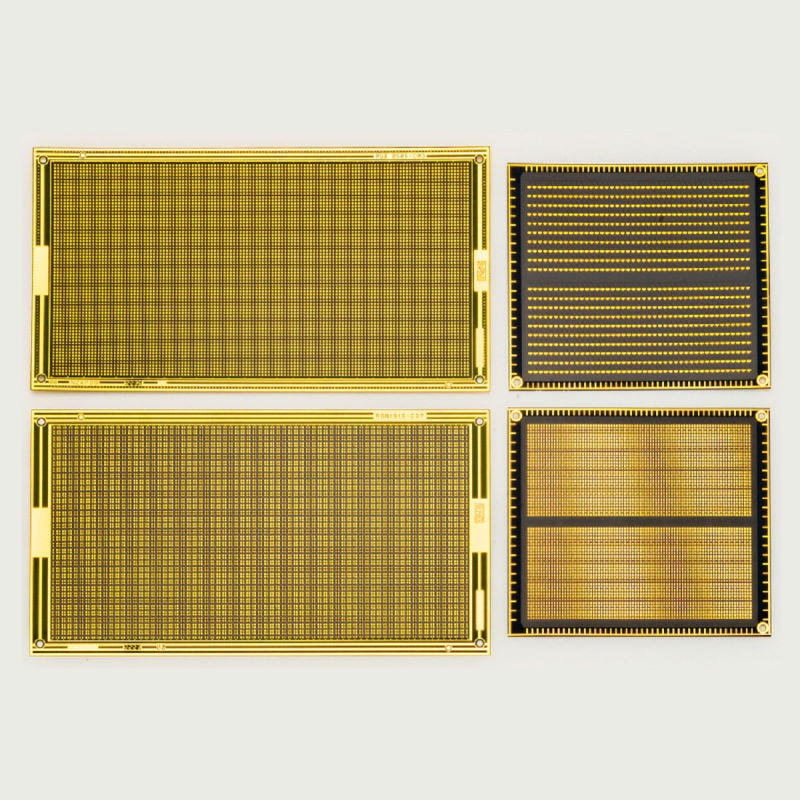

Mini LED & IC BT-like Substrate

We provide BT-like substrate with fine pattern, high density and thinner thickness by introducing Sumitomo Bakelite LaZ Roll type CCL and manufacturing by Mektec & JMC's Roll to Roll process.

Auto Molding Equipment / GTM-X 120/170T

GTM-X 120/170T (Transfer Molding system for large scale ECU) - Transfer molding system for efficient mass production of power semiconductors and large electronic devices. - Large-plate, high-output presses required for encapsulation of large devices. - Dual in-line plunger layout supports large package products. - Individual preheat stages ensure stable molding quality. - Large-capacity twin hopper for supplying mini tablets to large-sized packages. - Support for multiple mini tablets and high-cycle alignment to meet product tact time. - The number of presses can be selected according to the production volume by the module connection system.

Trim & Form Equipment / A-COMBO Series

Higher matrix and larger frame size for more productivity isbeing continued to the next stage, where the ordinary T/Fsystem can not comply. COMBO-300SW is new-released to comply to this kind of needs. This system can handle 300mmL x 100mmW, 8-linematrix frame. COMBO-300DC, which has tool compatibility with old A-COMBO is also available. - Continuous molding cycle of 140 spm is achievable by synchronized press operation and unique material handling mechanism. - Each function is modularized to accommodate the multifunctional front and rear processes of semiconductor manufacturing. - The system can be easily reconfigured and added after delivery. - In the trim & forming area of the machine, a full-open function is provided for the press mechanism used to drive the machine, making it easy to perform mold maintenance.

Auto Molding Equipment / LPM-600

LPM-600 (Realization of automatic molding of ultra-large panels of up to 620mm*620mm) - High precision TTV is realized by our original 4-axis linear motion structure press. - The TTV can be adjusted in micron units in a short time (minimum setting value: 1μm). - Both granule and liquid resin can be handled, making it possible to use for various process development. - The combination of the unique dynamic panel clamping technology and preheat function can be used for large warped products and brittle material panels. - Excellent panel positioning accuracy is achieved with the image processing alignment function. - The panel back side cleaning function is equipped as standard to prevent cracks and dents during molding. - The face-up (upper mold cavity) molding method enables molding of heavy and warped panels without the risk of product drop even under high vacuum molding. - Process monitoring and control functions maintain stable quality.

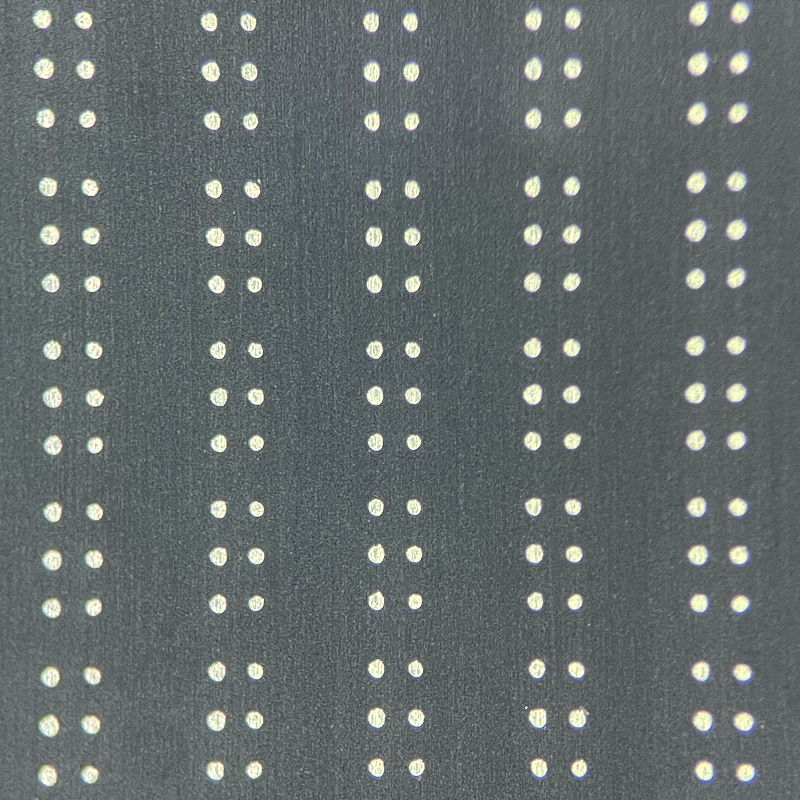

LED Lead Frame / Mini LED Lead Frame

CWE will provide integrated solution for manufacture. We have our own design, tooling developed, etching technology, plating technology and transfer molding technology( Epoxy) of LED Packing. It will become encapsulation material for die bonding, wire bonding, dispenser, making indispensable in the LED Packing factory. EMC: Epoxy Molding Compound EMC LED lead frame, what we call usually "Pre-Mold LED lead frame", will be applied to high-power LED package with a lead frame to provide a combination of copper and high-performance thermosetting plastics for SMD applications. The appreciation of thermosetting plastic has two applications, Epoxy and Silicon. The former will be the mainstream. CWTC develops EMC LED lead frame and it will become the mainstream in Epoxy lead frame and Mini LED lead frame field, which can be applied on displays and backlight products. The advantage of EMC LED lead frame is that we choose high-precision and high-productivity Etching Copper material, and we use Auto Molding system with high precision Molding Mold Chase for this highly integrated MAP Type LED package. It will have high density, high heat resistance, anti-yellowing, and high air pressurization to pass Red Ink Testing.