Product & Service

Opto-Electronic

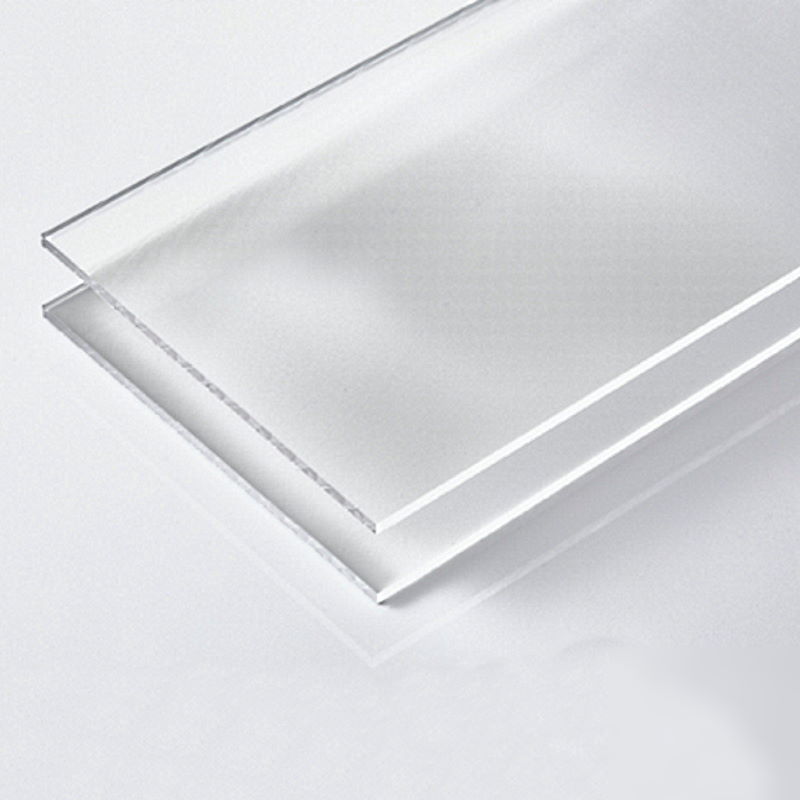

Light Guide Plate

CHIMEI’s ACRYSTEX® Optical MS Sheets are optical plates manufactured with CHIMEI-produced optical grade styrene methyl methacrylate (SMMA). These sheets feature good weather resistance, high heat resistance, high transparency and gloss, as well as stable physical, chemical, optical, and electrical properties. To drive the creation of ultra-narrow border and ultra-thin screens, ACRYSTEX® Optical MS Sheets offer low water absorption, meaning they maintain high dimensional stability. They are widely used in backlight and optical grade light guide plates, scanners, cover films, lighting signage, and backlight modules. This material is UL certified.

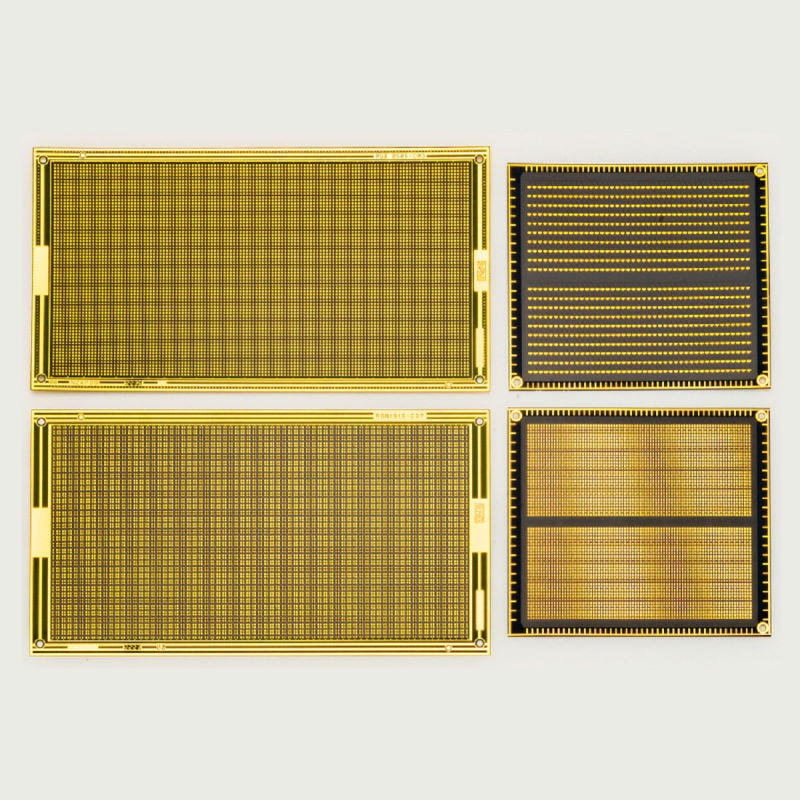

Mini LED & IC BT-like Substrate

We provide BT-like substrate with fine pattern, high density and thinner thickness by introducing Sumitomo Bakelite LaZ Roll type CCL and manufacturing by Mektec & JMC's Roll to Roll process.

Auto Molding Equipment / GTM-X 120/170T

GTM-X 120/170T (Transfer Molding system for large scale ECU) - Transfer molding system for efficient mass production of power semiconductors and large electronic devices. - Large-plate, high-output presses required for encapsulation of large devices. - Dual in-line plunger layout supports large package products. - Individual preheat stages ensure stable molding quality. - Large-capacity twin hopper for supplying mini tablets to large-sized packages. - Support for multiple mini tablets and high-cycle alignment to meet product tact time. - The number of presses can be selected according to the production volume by the module connection system.

GTM/GTM-X full auto mold equipment for LED production

The manual/Auto mold equipment matches the module design rule and also applies to LED packing territory. 1. Ability for Liquid Compound: Higher Power & Longer Life. Durability for Heat & Light. 2. Lower Cost production: Higher Productivity. Lesser Process. Capability for Low Cost Interposer (Lead Frame). 3. Smaller & Thinner Package: Freedom of Package design. Simple package design/construction.

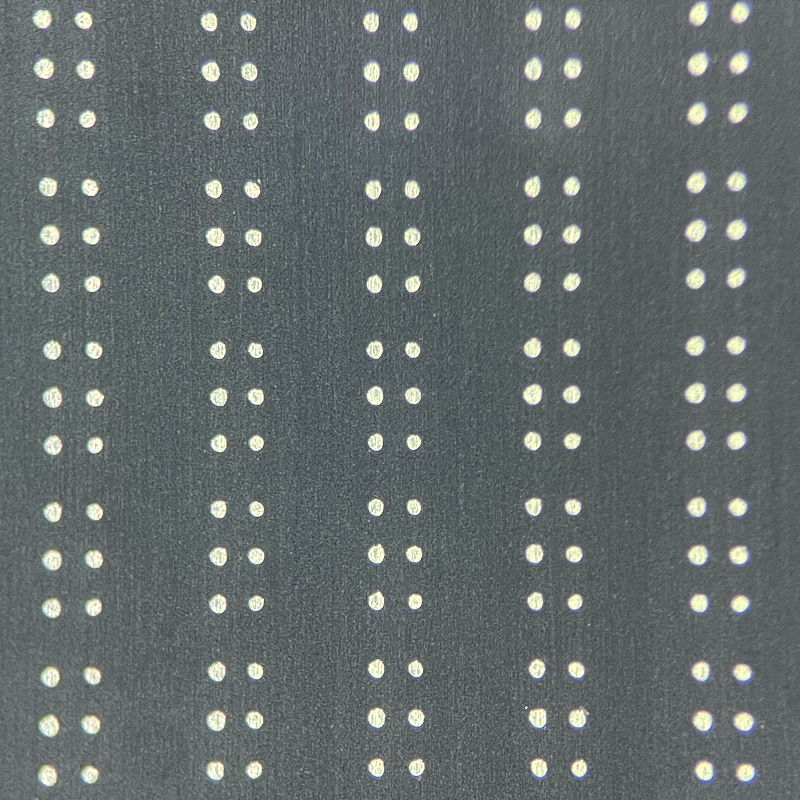

LED Lead Frame / Mini LED Lead Frame

CWE will provide integrated solution for manufacture. We have our own design, tooling developed, etching technology, plating technology and transfer molding technology( Epoxy) of LED Packing. It will become encapsulation material for die bonding, wire bonding, dispenser, making indispensable in the LED Packing factory. EMC: Epoxy Molding Compound EMC LED lead frame, what we call usually "Pre-Mold LED lead frame", will be applied to high-power LED package with a lead frame to provide a combination of copper and high-performance thermosetting plastics for SMD applications. The appreciation of thermosetting plastic has two applications, Epoxy and Silicon. The former will be the mainstream. CWTC develops EMC LED lead frame and it will become the mainstream in Epoxy lead frame and Mini LED lead frame field, which can be applied on displays and backlight products. The advantage of EMC LED lead frame is that we choose high-precision and high-productivity Etching Copper material, and we use Auto Molding system with high precision Molding Mold Chase for this highly integrated MAP Type LED package. It will have high density, high heat resistance, anti-yellowing, and high air pressurization to pass Red Ink Testing.