Product & Service

Energy

Solar Power System

We provide building solar systems and all applications of solar system identification for free. We allow customers pay partial fees based on contracts of solar energy equipment year by year. We ensure that the total combined generating capacity of 20-year quality assurance. We apply the 20 years Warranty which is free from the first year to the fifth year and offers discounts for repairs from the six year to the twenty year. Customers only rent out their buildings’ roof to us and allow us to build solar systems so customers could get rental monthly. Solar power system operation 。solar systems absorb energy of sun light and turn it into electric power. 。the generation of solar system could not be stored. 。All generation will be recorded by the new electric meter and sold out to TPC. 。But users still purchase low-cost electric power which is settled by the original electric meter. 。The gap of the different sources of electric power is subsidizes by the Government Energy Fundation. 。Carbon emissions of solar power is quite low which could partially replace traditional energy sources, and then reduce carbon emissions. Solar power system description 。Customers could sell NTD$10.3185/per degree by the operation of solar system but just pay around NTD$2.5/per degree for the whole electric fee. The benefits of building solar power systems 。To build more solar systems, reduce using nuclear energy and create a wonderful environment for our after springs. 。To industries, they could gain profits and enhance a high quality image 。PV modules can effectively reduce the indoor temperature and air-condition fee. 。To make buildings turn into green buildings is useful to protect the right of carbon trading in the future. Application What can CWE team do for you? 。Option I: The mode of building’s roof rental. 。Option II: The mode of solar equipment rental 。Option II: The mode of solar equipment rental Services: 1. We provide building solar systems and all applications of solar system identification for free. 2. We offer that the total combined generating capacity of 20-year-quality assurance. If the total generating capacity of 20 years is less than assurance we offered, we will indemnify to the customer. 3. We apply the 20 years Warranty which is free from the first year to the fifth year and offers discounts for repairs from the six year to the twenty year.

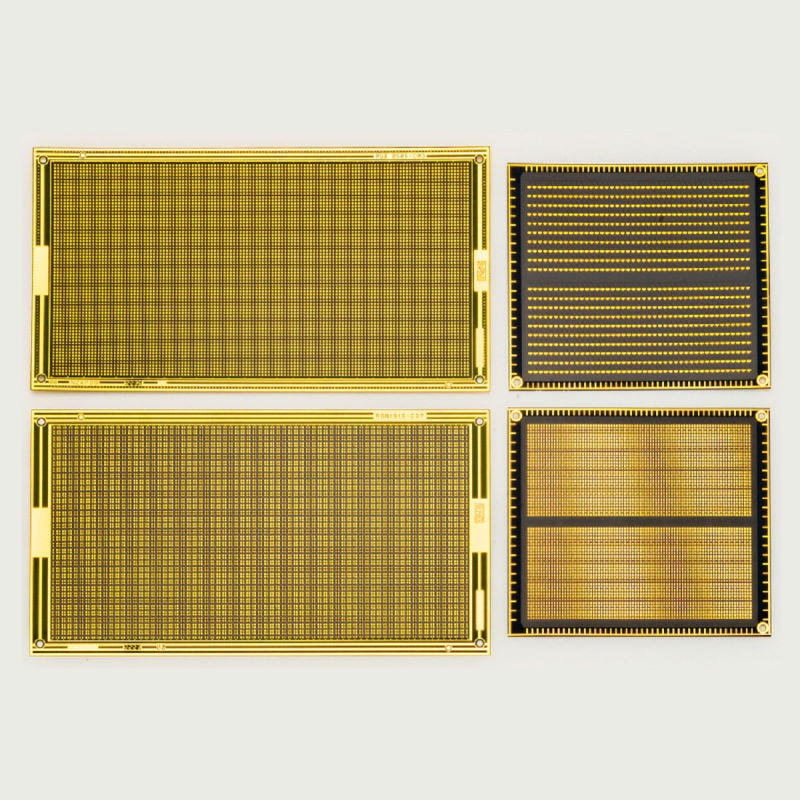

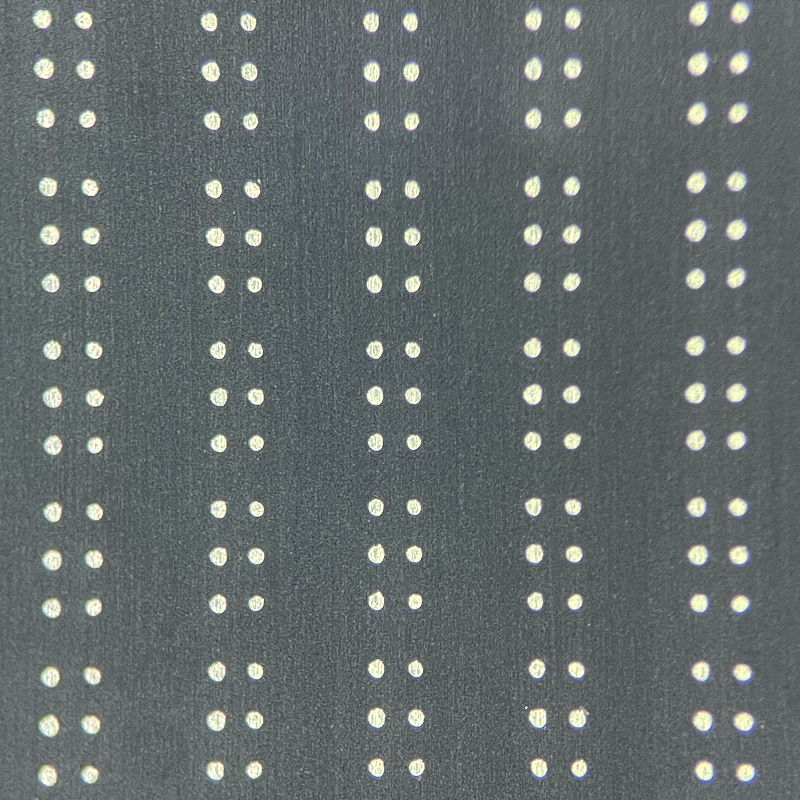

Mini LED & IC BT-like Substrate

We provide BT-like substrate with fine pattern, high density and thinner thickness by introducing Sumitomo Bakelite LaZ Roll type CCL and manufacturing by Mektec & JMC's Roll to Roll process.

Auto Molding Equipment / GTM-X 120/170T

GTM-X 120/170T (Transfer Molding system for large scale ECU) - Transfer molding system for efficient mass production of power semiconductors and large electronic devices. - Large-plate, high-output presses required for encapsulation of large devices. - Dual in-line plunger layout supports large package products. - Individual preheat stages ensure stable molding quality. - Large-capacity twin hopper for supplying mini tablets to large-sized packages. - Support for multiple mini tablets and high-cycle alignment to meet product tact time. - The number of presses can be selected according to the production volume by the module connection system.

GTM/GTM-X full auto mold equipment for LED production

The manual/Auto mold equipment matches the module design rule and also applies to LED packing territory. 1. Ability for Liquid Compound: Higher Power & Longer Life. Durability for Heat & Light. 2. Lower Cost production: Higher Productivity. Lesser Process. Capability for Low Cost Interposer (Lead Frame). 3. Smaller & Thinner Package: Freedom of Package design. Simple package design/construction.

LED Lead Frame / Mini LED Lead Frame

CWE will provide integrated solution for manufacture. We have our own design, tooling developed, etching technology, plating technology and transfer molding technology( Epoxy) of LED Packing. It will become encapsulation material for die bonding, wire bonding, dispenser, making indispensable in the LED Packing factory. EMC: Epoxy Molding Compound EMC LED lead frame, what we call usually "Pre-Mold LED lead frame", will be applied to high-power LED package with a lead frame to provide a combination of copper and high-performance thermosetting plastics for SMD applications. The appreciation of thermosetting plastic has two applications, Epoxy and Silicon. The former will be the mainstream. CWTC develops EMC LED lead frame and it will become the mainstream in Epoxy lead frame and Mini LED lead frame field, which can be applied on displays and backlight products. The advantage of EMC LED lead frame is that we choose high-precision and high-productivity Etching Copper material, and we use Auto Molding system with high precision Molding Mold Chase for this highly integrated MAP Type LED package. It will have high density, high heat resistance, anti-yellowing, and high air pressurization to pass Red Ink Testing.